| MEANING | TYC50-32 |

| T | Code of enterprise |

| Y | Submerged pump |

| C | Magnetic driven |

| 50 | The inlet dia is 50mm |

| 32 | Head is 32m |

一、Product Introduction:

FEATURES:

1.TYC no leakage double shell magnetic submerged pump is designed and manufactured according to HG/T2730-2012 and API685-2000.

2.The flowing-passed components like pump body, inner rotor, pump cover, impeller, distance sleeve, etc, are all made of superior stainless steel or special materials.

3.The flowing-passed components like pump body, inner rotor, pump cover, etc, are all precisly casted of ludox, no impurities, no air holes, no sand holes. Accurate size and smooth runner ensure anti-corrosion and pressure resistance of pump.

4.Impeller is designed and precision casted per CFD computer fluid mechanics and module design, with features of wide and smooth runner, high efficiency, good NPSH performance, small axial force, accurate size and good interchangeability.

6.Rotating ring, shaft sleeve, sleeve bearings are made of SSIC and tungsten carbide material with good characteristic of superior wear resistance, high strength and good anti-corrosion, which guarantee the pump’s working life.

7.New type permanent magnet with good magnetism, high temperature resistant and No demagnetization is selected.

8.The unique automatic axial force balance system, which makes the axial force is almost zero, produce only very minor mechanical friction during long-term running and operation

9.Double sliding bearings structure makes pump run more stable, makes medium flow more smoothly.

10.Enclosed static seal completely solves the problem of dielectric leakage.

Application:

Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range:design pressure1.6-5.0Mpa, flow1.8-400m3/h, head15-125m, power1.5-110kw

Applicable temperature:-20~350℃

NOTES:Please indicate during ordering if the proportion of medium is larger than 1.3mg/cm3. No idling running. No delivering medium with particles or crystalline.

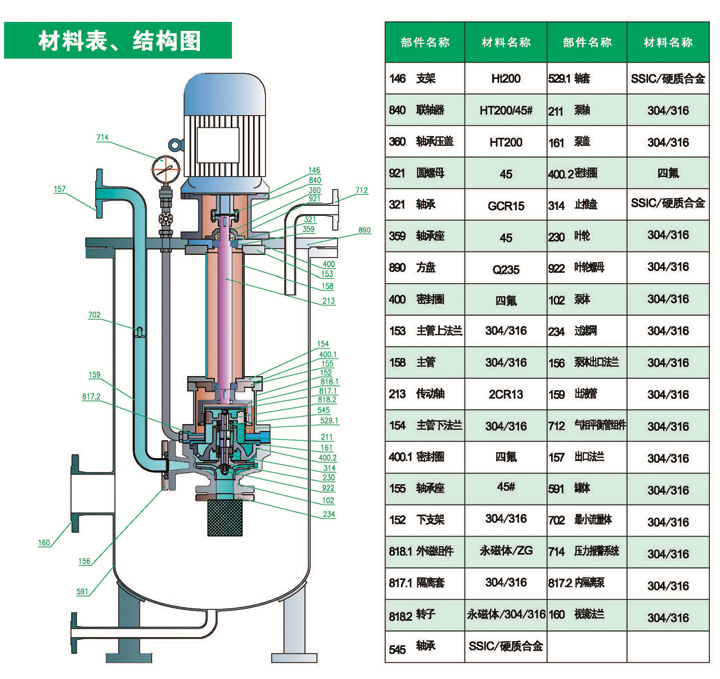

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| 146.bracket | Ht200 | 529.1.gasket | PTFE | 157.impeller | 304/316 |

| 840.coupling | HT200/45# | 211.bearing seat | 45# | 591.impeller nut | 304/316 |

| 360.bearing gland | HT200 | 161.below bracket | 304/316 | 702.pump body | 304/316 |

| 921.round nut | 45 | 4002.2.outer magnet assembly | permenant flange/ZG | 714.filter | 304/316 |

| 312.bearing | GCR15 | 314.distance sleeve | 304/316 | 917.outlet flange | 304/316 |

| 359.bearing seat | 45 | 230.rotor | permenant magnet/304/316 | outlet | 304/316 |

| 890.square plate | Q235 | 922.bearing | SSIC/hard alloy | 160.balance tube assembly | 304/316 |

| 400.gasket | PTFE | 102.shaft sleeve | SSIC/ hard alloy | outlet flange | 304/316 |

| 153.over flange of main pipe | 304/316 | 234.pump shaft | 304/316 | case body | 304/316 |

| 158.mian pipe | 304/316 | 156.pump cover | 304/316 | minimum flow volume | 304/316 |

| 213.transmision shaft | 2CR13 | 159.gasket | PTFE | pressure alarm sysytem | 304/316 |

| 154.below flange of main pipe | 304/316 | 712.thrust collar | SSIC/ hard alloy | inner isolation | 304/316 |

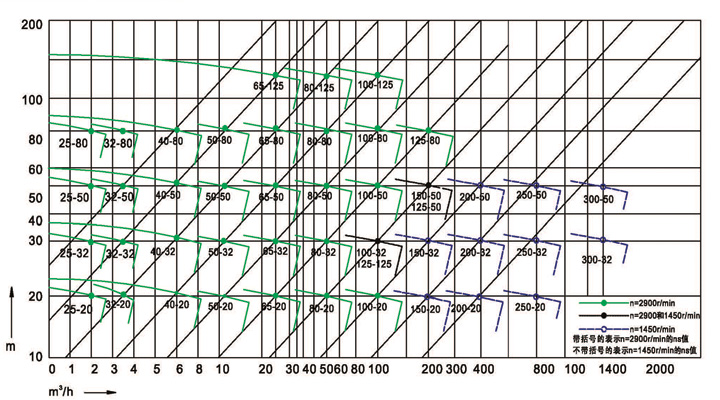

三、Performance Curve:

四、Performance data sheet:

| Type | Speed r/min |

Flow m3/h |

Head m |

Efficiency % |

NPS m |

Inlet×Outlet mm |

Power kw |

| 25TYCC-20 | 2900 | 1.5 | 22 | 28 | 2.5 | 25×20 | 2.2 |

| 2 | 20 | 34.5 | 2.5 | ||||

| 3.2 | 18.5 | 36 | 3 | ||||

| 25TYCC-32 | 2900 | 1.5 | 34.3 | 24 | 2.5 | 25×20 | 3 |

| 2 | 32 | 32 | 2.5 | ||||

| 3.2 | 29.6 | 33 | 3 | ||||

| 25TYCC-50 | 2900 | 1.5 | 52.5 | 28 | 2.5 | 25×20 | 5.5 |

| 2 | 50 | 32 | 2.5 | ||||

| 3.2 | 48 | 30 | 3 | ||||

| 25TYCC-80 | 2900 | 1.5 | 82 | 26 | 2.5 | 25×20 | 11 |

| 2 | 80 | 30 | 2.5 | ||||

| 3.2 | 78.5 | 28 | 3 | ||||

| 32TYCC-20 | 2900 | 2 | 22 | 40 | 2.5 | 32×20 | 2.2 |

| 3.2 | 20 | 44 | 2.5 | ||||

| 5.5 | 18.5 | 42 | 3 | ||||

| 32TYCC-32 | 2900 | 2 | 34.3 | 40 | 2.5 | 32×20 | 3 |

| 3.2 | 32 | 44 | 2.5 | ||||

| 5.5 | 29.6 | 42 | 3 | ||||

| 32TYCC-50 | 2900 | 2 | 52.5 | 32 | 2.5 | 32×20 | 5.5 |

| 3.2 | 50 | 36 | 2.5 | ||||

| 5.5 | 48 | 34 | 3 | ||||

| 32TYCC-80 | 2900 | 2 | 82 | 26 | 2.5 | 32×20 | 11 |

| 3.2 | 80 | 30 | 2.5 | ||||

| 5.5 | 78.5 | 28 | 3 | ||||

| 40TYCC-20 | 2900 | 4.4 | 22 | 41 | 2.5 | 40×25 | 2.2 |

| 6.3 | 20 | 46 | 2.5 | ||||

| 8.3 | 18.5 | 43 | 3 | ||||

| 40TYCC-32 | 2900 | 4.4 | 34.3 | 35 | 2.5 | 40×25 | 3 |

| 6.3 | 32 | 40 | 2.5 | ||||

| 8.3 | 29.6 | 38 | 3 | ||||

| 40TYCC-50 | 2900 | 4.4 | 52.5 | 26 | 2.5 | 40×25 | 7.5 |

| 6.3 | 50 | 33 | 2.5 | ||||

| 8.3 | 48 | 32 | 3 | ||||

| 40TYCC-80 | 2900 | 4.4 | 82 | 24 | 2.5 | 40×25 | 11 |

| 6.3 | 80 | 28 | 2.5 | ||||

| 8.3 | 78.5 | 28 | 3 | ||||

| 50TYCC-20 | 2900 | 7.5 | 22 | 43 | 2 | 50×32 | 3 |

| 12.5 | 20 | 51 | 2 | ||||

| 15 | 18.5 | 49 | 2.5 | ||||

| 50TYCC-32 | 2900 | 7.5 | 34.3 | 33 | 2 | 50×32 | 4 |

| 12.5 | 32 | 44.5 | 2 | ||||

| 15 | 29.6 | 46 | 2.5 | ||||

| 50TYCC-50 | 2900 | 7.5 | 52.5 | 28 | 2 | 50×32 | 7.5 |

| 12.5 | 50 | 37 | 2 | ||||

| 15 | 48 | 40.5 | 2.5 | ||||

| 50TYCC-80 | 2900 | 7.5 | 82 | 23 | 2 | 50×32 | 15 |

| 12.5 | 80 | 32 | 2 | ||||

| 15 | 78.5 | 36.5 | 2.5 | ||||

| 65TYCC-20 | 2900 | 15 | 21.8 | 37 | 2 | 65×50 | 4 |

| 25 | 20 | 57 | 2 | ||||

| 30 | 18.5 | 60 | 2.5 | ||||

| 65TYCC-32 | 2900 | 15 | 35 | 44 | 2 | 65×50 | 5.5 |

| 25 | 32 | 53 | 2 | ||||

| 30 | 30 | 57 | 2.5 | ||||

| 65TYCC-50 | 2900 | 15 | 53 | 41 | 2 | 65×40 | 11 |

| 25 | 50 | 50 | 2 | ||||

| 30 | 47 | 53.5 | 2.5 | ||||

| 65TYCC-80 | 2900 | 15 | 82 | 34 | 2 | 65×40 | 18.5 |

| 25 | 80 | 46 | 2 | ||||

| 30 | 78 | 50 | 2.5 | ||||

| 65TYCC-125 | 2900 | 15 | 127 | 28 | 2.5 | 65×40 | 30 |

| 25 | 125 | 39 | 2.5 | ||||

| 30 | 123 | 48.5 | 3 | ||||

| 80TYCC-20 | 2900 | 30 | 22.5 | 53 | 3 | 80×65 | 7.5 |

| 50 | 20 | 57 | 3 | ||||

| 60 | 18 | 47 | 3.5 | ||||

| 80TYCC-32 | 2900 | 30 | 36 | 52 | 2.5 | 80×65 | 11 |

| 50 | 32 | 62 | 2.5 | ||||

| 60 | 29 | 60 | 3 | ||||

| 80TYCC-50 | 2900 | 30 | 53 | 53 | 2.5 | 80×50 | 15 |

| 50 | 50 | 60 | 2.5 | ||||

| 60 | 47 | 58 | 3 | ||||

| 80TYCC-80 | 2900 | 30 | 84 | 44 | 2.5 | 80×50 | 30 |

| 50 | 80 | 55 | 2.5 | ||||

| 60 | 75 | 57 | 3 | ||||

| 80FY-125 | 2900 | 30 | 128 | 39 | 2.5 | 80×50 | 45 |

| 50 | 125 | 48 | 2.5 | ||||

| 60 | 123 | 47.5 | 3 | ||||

| 100TYCC-20 | 2900 | 60 | 24 | 59 | 4 | 100×80 | 11 |

| 100 | 20 | 67 | 4.5 | ||||

| 120 | 16.5 | 57 | 5 | ||||

| 100TYCC-32 | 2900 | 60 | 36 | 56 | 3.5 | 100×80 | 15 |

| 100 | 32 | 67 | 4 | ||||

| 120 | 28 | 68 | 5 | ||||

| 100TYCC-50 | 2900 | 60 | 54 | 57 | 3 | 100×65 | 30 |

| 100 | 50 | 67 | 3.6 | ||||

| 120 | 47 | 66 | 4.8 | ||||

| 100TYCC-80 | 2900 | 60 | 87 | 52 | 3.5 | 100×65 | 45 |

| 100 | 80 | 63 | 3.8 | ||||

| 120 | 74.5 | 62 | 4.8 | ||||

| 100TYCC-125 | 2900 | 60 | 133 | 48 | 3 | 100×65 | 75 |

| 100 | 125 | 57 | 3.6 | ||||

| 120 | 118 | 59 | 4.2 | ||||

| 125TYCC-20 | 2900 | 120 | 23 | 63 | 4.5 | 125×100 | 22 |

| 200 | 20 | 72 | 4.5 | ||||

| 240 | 18 | 65 | 5 | ||||

| 125TYCC-32 | 2900 | 120 | 35 | 57 | 3.8 | 125×100 | 30 |

| 200 | 32 | 70 | 4.2 | ||||

| 240 | 28 | 69 | 5 | ||||

| 125TYCC-50 | 1450 | 120 | 55 | 57 | 2.5 | 150×125 | 45 |

| 100 | 50 | 70 | 2.5 | ||||

| 240 | 45 | 67 | 3 | ||||

| 150TYCC-20 | 1450 | 120 | 132.5 | 56 | 4 | 125×100 | 22 |

| 200 | 20 | 65 | 4.5 | ||||

| 240 | 120 | 58 | 5 | ||||

| 150TYCC-32 | 1450 | 120 | 52 | 51 | 2.5 | 125×100 | 30 |

| 200 | 32 | 57 | 2.5 | ||||

| 240 | 48.5 | 53 | 3 | ||||

| 150TYCC-50 | 1450 | 120 | 53 | 56 | 2.5 | 150×125 | 45 |

| 200 | 50 | 65 | 2.8 | ||||

| 240 | 46 | 58 | 3.5 | ||||

| 200TYCC-20 | 1450 | 240 | 21.5 | 68 | 3.5 | 200×150 | 37 |

| 400 | 20 | 74 | 4.3 | ||||

| 460 | 17.5 | 70 | 5 | ||||

| 200TYCC-32 | 1450 | 240 | 37 | 62 | 3 | 200×150 | 75 |

| 400 | 32 | 74 | 3.5 | ||||

| 460 | 28.5 | 72 | 4 | ||||

| 200TYCC-50 | 1450 | 240 | 55 | 62 | 3 | 200×150 | 110 |

| 400 | 50 | 73 | 3.8 | ||||

| 460 | 45 | 70 | 4.5 | ||||

| 250TYCC-20 | 1450 | 600 | 22 | 75 | 4.1 | 250×200 | 75 |

| 800 | 20 | 78 | 5 | ||||

| 960 | 16 | 77 | 6 | ||||

| 250TYCC-32 | 1450 | 600 | 34 | 73 | 4.8 | 250×200 | 90 |

| 800 | 32 | 75 | 5.5 | ||||

| 960 | 28 | 75 | 6.4 | ||||

| 250TYCC-50 | 1450 | 600 | 54.5 | 55 | 3.5 | 250×200 | 160 |

| 800 | 50 | 68 | 4.3 | ||||

| 960 | 39 | 70 | 5 | ||||

| 300TYCC-32 | 1450 | 1550 | 35 | 58 | 3.6 | 300×250 | 220 |

| 1400 | 32 | 74 | 4.5 | ||||

| 1300 | 26 | 65 | 5.4 | ||||

| 300TYCC-50 | 1450 | 1550 | 55 | 65 | 4.1 | 300×250 | 315 |

| 1400 | 50 | 75 | 5 | ||||

| 1300 | 42.5 | 73 | 6 |

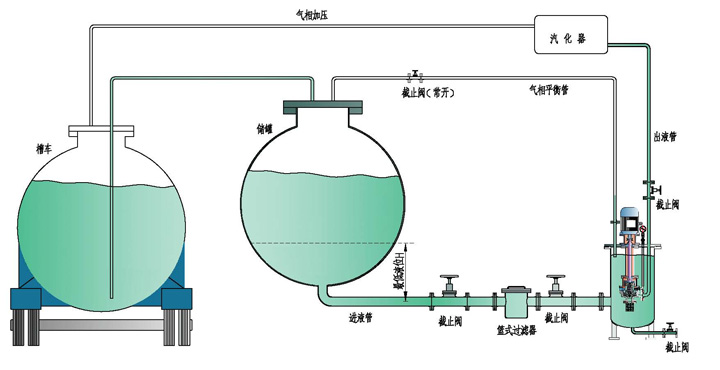

Installation sketch map and tanker working principal:

1.In order to avoid playing "stuffy pumps" and pump in cases with low flow operation, pump should be seted the minimum backflow;

2.In order to reduce the resistance, pump casing with liquid phase of liquid chlorine tank liquid inlet pipe DN100-diameter pipe at least is recommended

3.Between the pump casing and tank vapor and liquid through the valve in the piping layout control should be achieved independently

4.Minimum liquid level(H):HNPSHr(m)+pipeline loss(m)+0.5(m);

5.The proposal is equipped with frequency converter to adjust the pump outlet pressure and flow rate

6.Recommendations are fitted with flow meter to monitor the flow and avoid excessive flow run damage the pump

7.If the impurity in liquid chlorine, recommended inlet pipe set the basket filter (30 or 40 mesh).

Working principal:

With liquid chlorine pump liquid chlorine is fed into the carburetor, carbure to chloride produces high pressure tank chloride vapor pressure, liquid chlorine tank into the tank of liquid chlorine to achieve safety of liquid chlorine tank car.

Virtual product: