| MEANING | TLY25-200 |

| T | Code of enterprise |

| Y | Vertical llong shaft |

| L | Submerged pump |

| 25 | The inlet dia is 25mm |

| 200 | Nominal dia of impeller is 200mm |

一、Product Introduction:

FEATURES:

1.TY submerged pump is new type industrial pump.

2.The flowing-passed components like pump body, inner rotor, pump cover, impeller, distance sleeve, etc, are all made of superior stainless steel or special materials.

3.Hydraulic components is designed and precision casted per CFD computer fluid mechanics and module design, with features of wide and smooth runner, high efficiency, good NPSH performance, small axial force, accurate size and good interchangeability.

4. Shaft sleeve and sliding bearing are made from SSIC and tungsten carbide with features of superior anti-corrosion, abrasive resistance, heat resistance and good self-lubrication, lubrication groove setting, all of these guarantee its long working life and stable running.

5.No need of filling with liquid to work. The depth can reach 8m.

6.No need of independent lubrication and cooling water, reducing energy consumption.

7.Vertical mount, compact structure, low voice, small vibration, small occupation and stable operation.

8.Customized heating type or high-temperature type per requested.

Application: Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range: design pressure 1.6-10Mpa, flow 1.8-400m3/h, head 15-125m, power 1.5-280kw

Applicable temperature: -20~120℃, can be up to 350℃ if using new type material.

NOTES: Please indicate during ordering if the proportion of medium is larger than 1.3mg/cm3. No idling running. No delivering medium with particles or crystalline.。

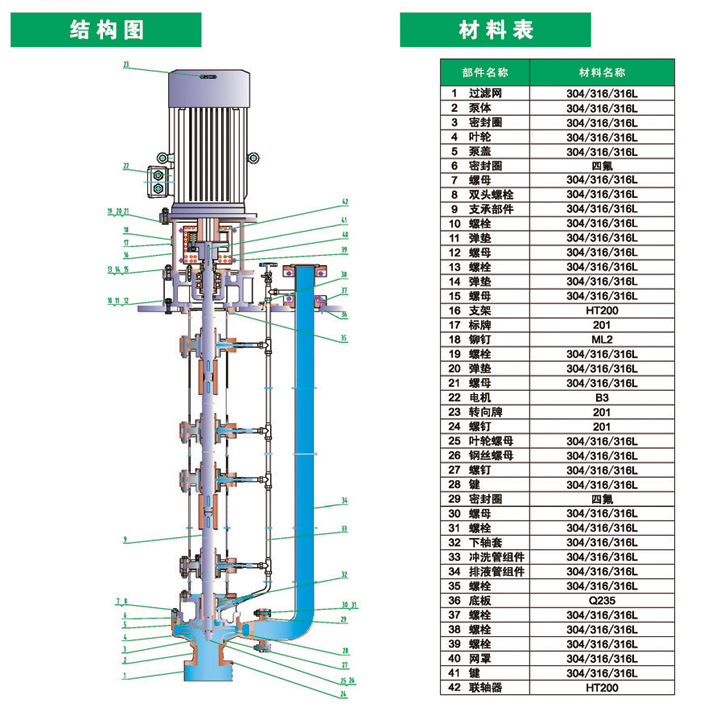

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| 1.filter screen | 304/316/316L | 15.mut | 304/316/316L | 29.impeller nut | PTFE |

| 2.pump body | 304/316/316L | 16.bracket | HT200 | 30.impeller nut | 304/316/316L |

| 3.gasket | 304/316/316L | 17.name tag | 201 | 31.impeller nut | 304/316/316L |

| 4.impeller | 304/316/316L | 18.rivet | ML2 | 32.impeller nut | 304/316/316L |

| 5.pump cover | 304/316/316L | 19.stud | 304/316/316L | 33.impeller nut | 304/316/316L |

| 6.gasket | PTFE | 20.spring washer | 304/316/316L | 34.impeller nut | 304/316/316L |

| 7.nut | 304/316/316L | 21.nut | 304/316/316L | 35.impeller nut | 304/316/316L |

| 8.bolt stud | 304/316/316L | 221motor | B3 | 36.impeller nut | Q235 |

| 9.supporting components | 304/316/316L | 23.direction tag | 201 | 37.stud | 304/316/316L |

| 10.stud | 304/316/316L | 24.bolt | 201 | 38.stud | 304/316/316L |

| 11.spring washer | 304/316/316L | 25.impeller nut | 304/316/316L | 39.stud | 304/316/316L |

| 12.nut | 304/316/316L | 26.impeller nut | 304/316/316L | 40.mesh cover | 304/316/316L |

| 13.stud | 304/316/316L | 27.impeller nut | 304/316/316L | 41.key | 304/316/316L |

| 14.spring washer | 304/316/316L | 28.impeller nut | 304/316/316L | 42.coupling | HT200 |

三、Performance data sheet:

| Type | Impeller | Motor speed n~2950r/min | Motor speed n~1475r/min | ||||||||||

| Flow Q M3/ |

Head H m |

Proportion Y=100 | Proportion Y=135 | Flow Q M3/ |

Head H m |

Proportion Y=100 | Proportion Y=135 | ||||||

| Motor power and type | 电机功率及型号 | ||||||||||||

| KW | Frame size | KW | Frame size | KW | Frame size | KW | Frame size | ||||||

| SLY25-200 | A | 11.5 | 47 | 5.5 | 132S1-2 | 7.5 | 132S2-2 | 5.8 | 11 | 1.1 | 90S-4 | 1.1 | 90S-4 |

| B | 10.5 | 40 | 4 | 112M-2 | 5.5 | 132S1-2 | 5.4 | 10 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| C | 9 | 34 | 3 | 100L-2 | 4 | 112M-2 | 4.6 | 7.5 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| D | 7.5 | 26 | 2.2 | 90L-2 | 3 | 100L-2 | 4 | 5.5 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| E | 5.5 | 14 | 1.5 | 90S-2 | 1.5 | 90S-2 | 3 | 3 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| SLY40-160 | A | 28 | 31 | 5.5 | 132S1-2 | 7.5 | 132S2-2 | 14 | 7 | 1.1 | 90S-4 | 1.1 | 90S-4 |

| B | 25.6 | 27 | 5.5 | 132S1-2 | 7.5 | 132S2-2 | 13 | 6 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| C | 22 | 20 | 4 | 112M-2 | 5.5 | 132S1-2 | 11 | 4.5 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| D | 20 | 14 | 2.2 | 90L-2 | 3 | 100L-2 | 9.5 | 3.5 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| SLY40-200 | A | 29 | 51 | 11 | 160M1-2 | 15 | 160M2-2 | 14.5 | 12 | 1.5 | 90L-4 | 2.2 | 100L1-4 |

| B | 26 | 45 | 7.5 | 132S2-2 | 11 | 160M1-2 | 13 | 10.5 | 1.1 | 90S-4 | 1.5 | 90L-4 | |

| C | 22 | 37 | 5.5 | 132S1-2 | 7.5 | 132S2-2 | 11.5 | 8 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| D | 18 | 18 | 4 | 112M-2 | 5.5 | 132S1-2 | 9.5 | 6 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| SLY40-250 | A | 32 | 76 | 18.5 | 160L-2 | 22 | 180M-2 | 16 | 18.5 | 3 | 100L2-4 | 4 | 112M-4 |

| B | 30 | 70 | 15 | 160M2-2 | 18.5 | 160L-2 | 15 | 17 | 2.2 | 100L1-4 | 3 | 100L2-4 | |

| C | 24 | 58 | 11 | 160M1-2 | 15 | 160M2-2 | 12.5 | 13 | 1.5 | 90L-4 | 2.2 | 100L1-4 | |

| D | 21 | 45 | 7.5 | 132S2-2 | 11 | 160M1-2 | 10.5 | 10 | 1.1 | 90S-4 | 1.5 | 90L-4 | |

| SLY40-315 | A | 21 | 28 | 5.5 | 132S-4 | 7.5 | 132M-4 | ||||||

| B | 20 | 26.5 | 5.5 | 132S-4 | 7.5 | 132M-4 | |||||||

| C | 11.8 | 19 | 4 | 112M-4 | 5.5 | 132S-4 | |||||||

| D | 15 | 14 | 3 | 100L2-4 | 3 | 100L2-4 | |||||||

| SLY50-160 | A | 50 | 32 | 11 | 160M1-2 | 15 | 160M2-2 | 25 | 7.5 | 1.5 | 90L-4 | 2.2 | 100L1-4 |

| B | 45 | 27 | 7.5 | 132S2-2 | 11 | 160M1-2 | 22.8 | 6 | 1.5 | 90L-4 | 1.5 | 90L-4 | |

| C | 38 | 20 | 5.5 | 132S1-2 | 7.5 | 132S2-2 | 19 | 45 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| D | 31 | 15 | 3 | 100L-2 | 4 | 112M-2 | 16.5 | 3 | 1.1 | 90S-4 | 1.1 | 90S-4 | |

| SLY50-200 | A | 62 | 50 | 18.5 | 160L-2 | 22 | 180M-2 | 31 | 12 | 3 | 100L1-4 | 3 | 100L2-4 |

| B | 56 | 44 | 15 | 160M2-2 | 18.5 | 160L-2 | 28.5 | 10.5 | 2.2 | 100L2-4 | 3 | 100L2-4 | |

| C | 49 | 35 | 11 | 160M1-2 | 15 | 160M2-2 | 25 | 8 | 1.5 | 90L-4 | 2.2 | 100L1-4 | |

| D | 43 | 26 | 7.5 | 132S2-2 | 11 | 160M1-2 | 22 | 6 | 1.1 | 90S-4 | 1.5 | 90L-4 | |

| SLY50-250 | A | 70 | 80 | 30 | 200L1-2 | 37 | 200L2-2 | 35 | 19 | 4 | 112M-4 | 5.5 | 132S-4 |

| B | 66 | 73 | 30 | 200L1-2 | 37 | 200L2-2 | 33 | 17.5 | 4 | 112M-4 | 5.5 | 132S-4 | |

| C | 60 | 58 | 22 | 180M-2 | 30 | 200L1-2 | 30 | 14 | 3 | 100L2-4 | 4 | 112M-4 | |

| D | 50 | 43 | 15 | 160M2-2 | 18.5 | 160L-2 | 26 | 10 | 2.2 | 100L1-4 | 3 | 100L2-4 | |

| SLY50-315 | A | 44 | 27 | 11 | 160M-4 | 11 | 160M-4 | ||||||

| B | 40 | 23 | 7.5 | 132M-4 | 11 | 160M-4 | |||||||

| C | 35 | 16 | 5.5 | 132S-4 | 7.5 | 132M-4 | |||||||

| D | 30 | 13 | 3 | 100L2-4 | 4 | 112M-4 |

| Type | Impeller | Motor speed n~2950r/min | Motor speed n~1475r/min | ||||||||||

| Flow Q M3/ |

Head H m |

Proportion Y=100 | Proportion Y=135 | Flow Q M3/ |

Head H m |

Proportion Y=100 | Proportion Y=135 | ||||||

| Motor power and type | 电机功率及型号 | ||||||||||||

| KW | Frame size | KW | Frame size | KW | Frame size | KW | Frame size | ||||||

| SLY80-315 | A | 70 | 32 | 15 | 160L-4 | 18.5 | 180M-4 | ||||||

| B | 66 | 29 | 11 | 160M-4 | 15 | 160L-4 | |||||||

| C | 56 | 23 | 11 | 160M-4 | 11 | 160M-4 | |||||||

| D | 45 | 17 | 5.5 | 132S-4 | 7.5 | 132M-4 | |||||||

| SLY100-160 | A | 162 | 27 | 22 | 180M-2 | 30 | 200L1-2 | 81 | 6.5 | 3 | 100L2-4 | 4 | 112M-4 |

| B | 150 | 22 | 15 | 160M2-2 | 22 | 180M-2 | 73 | 5 | 2.2 | 100L1-4 | 3 | 100L2-4 | |

| C | 130 | 15 | 11 | 160M1-2 | 15 | 160M2-2 | 63 | 3.3 | 1.5 | 90L-4 | 2.2 | 100L1-4 | |

| D | 110 | 10 | 7.5 | 132S2-2 | 11 | 160M1-2 | 55 | 2 | 1.1 | 90S-4 | 1.5 | 90L-4 | |

| SLY100-200 | A | 193 | 48 | 45 | 225M-2 | 55 | 250M-2 | 95 | 11.5 | 5.5 | 132S-4 | 7.5 | 132M-4 |

| B | 180 | 42 | 37 | 200L2-2 | 45 | 225M-2 | 90 | 9.5 | 5.5 | 132S-4 | 7.5 | 132M-4 | |

| C | 155 | 33 | 30 | 200L1-2 | 37 | 200L2-2 | 80 | 7.5 | 4 | 112M-4 | 5.5 | 132S-4 | |

| D | 135 | 24 | 18.5 | 160L-2 | 30 | 200L1-2 | 70 | 5 | 3 | 100L2-4 | 3 | 100L2-4 | |

| SLY100-250 | A | 230 | 77 | 75 | 280S-2 | 90 | 280M-2 | 115 | 19 | 11 | 160M-4 | 15 | 160L-4 |

| B | 218 | 71 | 75 | 280S-2 | 90 | 280M-2 | 110 | 17 | 11 | 160M-4 | 11 | 160M-4 | |

| C | 190 | 56 | 45 | 225M-2 | 75 | 280S-2 | 100 | 13 | 7.5 | 132M-4 | 11 | 160M-4 | |

| D | 170 | 42 | 37 | 200L2-2 | 45 | 225M-2 | 90 | 9 | 5.5 | 132S-4 | 7.5 | 132M-4 | |

| SLY100-315 | A | 125 | 30 | 18.5 | 180L-4 | 30 | 200L-4 | ||||||

| B | 119 | 28 | 18.5 | 180M-4 | 22 | 180L-4 | |||||||

| C | 104 | 23 | 15 | 160L-4 | 18.5 | 180M-4 | |||||||

| D | 86 | 16.5 | 11 | 160M-4 | 11 | 160M-4 | |||||||