| MEANING | 50TCWB80-45 |

| T | Code of enterprise |

| C | Magnetic driven |

| W | Vortex type |

| 50 | The inlet dia is 50mm |

| 45 | Head is 45m |

一、Product Introduction:

FEATURES:

1.TCW no leakage magnetic vortex pump is designed and manufactured accroding to HG/T 2730-2012.

2.The flowing-passed components like pump body, inner rotor, pump cover, impeller, distance sleeve, etc, are all made of superior stainless steel or special materials.

3.Hydraulic components is designed and precision casted per CFD computer fluid mechanics and module design, with features of wide and smooth runner, high efficiency, good NPSH performance, small axial force, accurate size and good interchangeability.

4.Distance sleeve is made of 316L, TA2, HC276 material quality and the low vortex sleeve design, distance sleeves are in a sinusoidal alternating magnetic field, in the direction perpendicular to the magnetic field lines of induced eddy currents on the section and converted into heat.You can choose high resistivity and strength of non-metallic materials production isolation sets, in terms of reduced Eddy current effect is obvious, eliminating all the excess calories to reduce energy consumption;Bursting with high pressure, high safety factor and pump Chamber is completely isolated from the outside world, the pump room is completely sealed, without any leakage during the transport.

5.Rotating ring, shaft sleeve and sliding bearings are made of SSIC and tungsten carbide material with good characteristic of superior wear resistance, high temperature resistance and anti-corrosion, which guarantee the pump’s working life.

6.Ferrite magnet with good magnetism, high temperature resistant and no demagnetization is selected.

7.The unique automatic axial force balance system, which makes the axial force is almost zero, produce only very minor mechanical friction during long-term running and operation.

8.Double sliding bearing structure makes medium flow more smoothly.

9.Enclosed static seal completely solves the problem of dielectric leakage.

Application: Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range:design pressure: 1.6-6.4Mpa, flow: 2-20m3/h, head:20-135m, power: 1.1-11kw

Applicable temperature:-20~120℃, can be -20~400℃ if using new type material.

The optional accessories:monitoring of leakage device, monitoring of temperature device, preventive idling running device.

NOTES: Please indicate during ordering if the proportion of medium is larger than 1.3mg/cm3. No delivering medium with particles or crystalline.

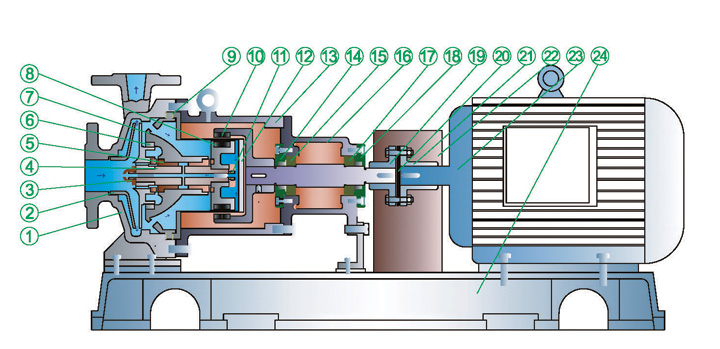

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| Pump cover | 304/316/316L | Thrust collar | Filled with PTFE | Inner rotor assembly | permenant magnet/304/316/316L |

| Gasket | PTFE | Pump shaft | 304/316/316L | Outer rotor assembly | permenant magnet/HT200 |

| Pump body | 304/316/316L | Baering | GRAPHITE | Connecting | HT200 |

| Impeller | 304/316/316L | Distance sleeve | 304/316/316L | Motor | Per clients requested |

三、Performance data sheet:

|

Type |

Flow(M3/h) |

Head(m) |

Speed(rpm) |

Motor(kW) |

Efficiencyη(%) |

Self-priming |

Impeller |

Weight(kg) |

|

20TCW-20 |

0.72 |

20 |

2900 |

0.75 |

22 |

6 |

65 |

26 |

|

20TCW-40 |

0.72 |

40 |

2900 |

1.1 |

18 |

6 |

90 |

32 |

|

20TCW-65 |

0.72 |

65 |

2900 |

2.2 |

15 |

6 |

105 |

36 |

|

25TCW-25 |

1.44 |

25 |

2900 |

1.1 |

26 |

5 |

75 |

28 |

|

25TCW-40 |

1.44 |

40 |

2900 |

1.5 |

24 |

5 |

90 |

40 |

|

25TCW-75 |

1.44 |

75 |

2900 |

4 |

20 |

5 |

110 |

55 |

|

30TCW-30 |

2.88 |

30 |

2900 |

2.2 |

28 |

5 |

90 |

38 |

|

32TCW-50 |

2.88 |

50 |

2900 |

3 |

26 |

5 |

100 |

52 |

|

32TCW-75 |

2.88 |

75 |

2900 |

7.5 |

22 |

5 |

120 |

76 |

|

32TCW-120 |

2.88 |

120 |

2900 |

11 |

18 |

4.5 |

140 |

95 |

|

40TCW-40 |

5.4 |

40 |

2900 |

4 |

30 |

4 |

100 |

70 |

|

40TCW-90 |

5.4 |

90 |

2900 |

11 |

26 |

3.5 |

130 |

105 |

|

50TCW-45 |

9 |

45 |

2900 |

7.5 |

30 |

4 |

110 |

92 |

|

65TCW-50 |

14.4 |

50 |

2900 |

15 |

35 |

3.5 |

120 |

158 |