| (配API610冲洗方案) |

| MEANING | TZE25-200 |

| T | Code of enterprise |

| ZE | Center support |

| 25 | The outlet dia is 25mm |

| 200 | Nominal dia of impeller is 200mm |

一、Product Introduction:

BRIEF:

TZE/ZE petroleum chemical process centrifugal pump is designed and produced per API 682 and VDMA24297. The pump body of TZE series is supported by feet, center support for TZE series. The impeller is radial and type of single suction, which is axial suction and radial discharge. Hydraulic equilibrium is used on front choma, back choma and balance pipe per operating conditions. Stuffing box has cooling or heating union joints. Shaft seal is sealed with stuffing, also can use single or double mechanical seal. Equipped with cooling and flushing or sealing fluid system.

Features:

1.TZE/ZE chemical process pump is application of standard pipe design per API standard. There are 3 types of impeller, closed, half-open and open. Clean media, media with particles, media with a little bit of gas, media with high temperature, media with low temperature or strong corrosive media all can be conveyed by TZE/ZE series pump. The impeller with balance pipe and anti-corrosion ring can balance axial force.

2.The pump body and bearing frame are connected by middle connecting section that can be used different material to avoid corrosion of bearing and bearing frame when conveying strong corrosive media per working conditions. At the same time, the middle connecting section is equipped with hydrocooling channel that connecting circulation cooling water, stopping high temperature media and transferring high temperature to bearings.

3.There are various sealing ways, like stuffing seal, single mechanical seal, double mechanical seal and container type single mechanical seal. The way of sealing can be selected according to API682 design standard, working conditions and clients’ requests of cooling and washing.

4.The bearing frame is designed to three types of air cooling fin, air cooling fan and hydrocooling channel, customers can decide on working conditions. The oil in the fuel tank is cooled by water in hydrocooling channel, the heat on the bearing taken away by water, which ensures bearing keep in working condition at any time.

Application: Be capable of conveying any temperature and concentration of organic or inorganic acid solutions like sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, etc.; salt solutions; alkaline solutions like sodium hydroxide, sodium carbonate, etc.; liquid petroleum chemical products; organic compounds and other corrosive liquids. This series pumps are usually applied to oil refineries, petrochemical industry, coal processing, cryogenic engineering, paper industry, sugar industry, water supply plant, desalination plants, power plants, environmental engineering and ships, etc. The direction of pump rotation is clockwise if looking from the motor end.

Performance range: Diamenson:25~400mm, flow: 5.5~2600m3/h, head: 16~250m

Working pressure: 2.5MPa(TZE),5.0 MPa(TZE), Working temperature:-80℃~ +120℃(TZE),-80℃~ +450℃(TZE

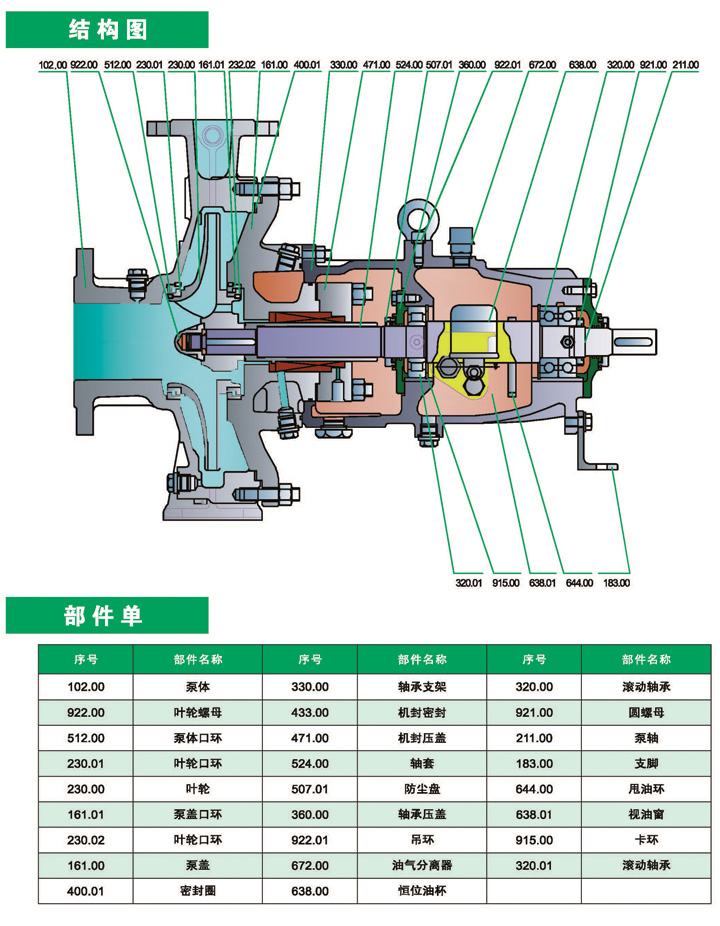

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| 102 | pump body | 330 | bearing bracket | 320 | rolling bearing |

| 922 | impeller nut | 433 | seal | 921 | round nut |

| 512 | choma of pump body | 471 | gland | 211 | pump shaft |

| 230.01 | choma of impeller nut | 524 | shaft sleeve | 183 | stand bar |

| 230 | impeller | 507.01 | dust-free plate | 644 | oil slinger |

| 161.01 | choma of impeller cover | 360 | bearing gland | 638.01 | oil window |

| 230.02 | impeller choma | 922.01 | lifting ring | 915 | snap ring |

| 161 | pump cover | 672 | oil and gas separator | 320.01 | rolling bearing |

| 400.01 | gasket | 638 | oil cup |

三、Performance data sheet:

| Type | Impeller type |

Flow | Head | Efficiency | Bearing frame | NPSH | Speed | proportion=1.00 | proportion=1.35 | proportion=1.84 |

| Q | H | η | LK | n | Type | |||||

| m3/h | m | % | m | r/min | kw | kw | kw | |||

| TZE25-200 | A | 11.5 | 49 | 42 | 0 | 1.5 | 2900 | 5.5 | 7.5 | 11 |

| 5.8 | 12 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.5 | |||

| B | 10.5 | 42 | 42 | 1.5 | 2900 | 4 | 5.5 | 7.5 | ||

| 5.4 | 11 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| C | 9 | 36 | 42 | 1.5 | 2900 | 3 | 4 | 5.5 | ||

| 4.6 | 8.5 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| D | 7.5 | 28 | 42 | 1.5 | 2900 | 2.2 | 3 | 4 | ||

| 4 | 6.5 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| E | 5.5 | 16 | 42 | 1.5 | 2900 | 1.5 | 1.5 | 2.2 | ||

| 3 | 4 | 38 | 0.6 | 1450 | 1.1 | 1.1 | 1.1 | |||

| TZE25-250 | A | 10.5 | 80 | 28 | 2 | 1.2 | 2900 | 11 | 15 | 18.5 |

| 7.5 | 18 | 23 | 1 | 1 | 1450 | 2.2 | 3 | 4 | ||

| B | 9.7 | 68 | 28 | 2 | 1.2 | 2900 | 7.5 | 11 | 15 | |

| 7 | 16 | 23 | 1 | 1 | 1450 | 2.2 | 3 | 4 | ||

| C | 9 | 50 | 28 | 2 | 1.2 | 2900 | 5.5 | 11 | 15 | |

| 6.5 | 11.5 | 23 | 1 | 1 | 1450 | 2.2 | 2.2 | 3 | ||

| D | 8.5 | 30 | 28 | 2 | 1.2 | 2900 | 5.5 | 11 | 15 | |

| 6 | 6.5 | 23 | 1 | 1 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZE25-315 | A | 18.5 | 130 | 28 | 2 | 1.2 | 2900 | 30 | 45 | 55 |

| 9.5 | 32 | 25 | 0.7 | 1450 | 5.5 | 7.5 | 11 | |||

| B | 17.5 | 115 | 28 | 1.2 | 2900 | 30 | 37 | 45 | ||

| 8.7 | 29 | 25 | 0.7 | 1450 | 4 | 5.5 | 7.5 | |||

| C | 16 | 100 | 28 | 1.2 | 2900 | 22 | 30 | 45 | ||

| 7.5 | 25 | 25 | 0.7 | 1450 | 3 | 4 | 5.5 | |||

| D | 14 | 90 | 28 | 1.2 | 2900 | 18.5 | 30 | 37 | ||

| 7 | 22 | 25 | 0.7 | 1450 | 3 | 4 | 5.5 | |||

| E | 13 | 80 | 28 | 1.2 | 2900 | 18.5 | 22 | 30 | ||

| 6.8 | 20 | 25 | 0.7 | 1450 | 3 | 4 | 5.5 | |||

| F | 11.5 | 67 | 28 | 1.2 | 2900 | 15 | 18.5 | 30 | ||

| 6 | 16 | 25 | 0.7 | 1450 | 2.2 | 3 | 4 | |||

| TZE40-160 | A | 28 | 33 | 62 | 2 | 3 | 2900 | 5.5 | 7.5 | 11 |

| 14 | 8 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| B | 25.6 | 29 | 62 | 2 | 3 | 2900 | 5.5 | 7.5 | 11 | |

| 13 | 7 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| C | 22 | 22 | 62 | 2 | 3 | 2900 | 4 | 5.5 | 5.5 | |

| 11 | 5.5 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| D | 20 | 16 | 62 | 2 | 3 | 2900 | 2.2 | 3 | 4 | |

| 9.5 | 4.5 | 59 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| TZE40-200 | A | 29 | 53 | 58 | 1 | 2.2 | 2900 | 11 | 15 | 18.5 |

| 14.5 | 13 | 55 | 1 | 0.8 | 1450 | 1.5 | 2.2 | 3 | ||

| B | 26 | 47 | 58 | 1 | 2.2 | 2900 | 7.5 | 11 | 15 | |

| 13 | 11.5 | 55 | 1 | 0.8 | 1450 | 1.1 | 1.5 | 3 | ||

| C | 22 | 39 | 58 | 1 | 2.2 | 2900 | 5.5 | 7.5 | 11 | |

| 11.5 | 9 | 55 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| D | 18 | 20 | 58 | 1 | 2.2 | 2900 | 4 | 5.5 | 7.5 | |

| 9.5 | 7 | 55 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| TZE40-250 | A | 32 | 78 | 53 | 1 | 2.5 | 2900 | 18.5 | 22 | 30 |

| 16 | 19.5 | 49.5 | 1 | 0.8 | 1450 | 3 | 4 | 5.5 | ||

| B | 30 | 72 | 53 | 1 | 2.5 | 2900 | 15 | 18.5 | 30 | |

| 15 | 18 | 49.5 | 1 | 0.8 | 1450 | 2.2 | 3 | 4 | ||

| C | 24 | 60 | 53 | 1 | 2.5 | 2900 | 11 | 15 | 18.5 | |

| 12.5 | 14 | 49.5 | 1 | 0.8 | 1450 | 1.5 | 2.2 | 3 | ||

| D | 21 | 47 | 53 | 1 | 2.5 | 2900 | 7.5 | 11 | 15 | |

| 10.5 | 10 | 49.5 | 1 | 0.8 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZE40-315 | A | 42 | 115 | 46 | 2 | 1.3 | 2900 | 37 | 45 | 75 |

| 21 | 29 | 42 | 2 | 0.5 | 1450 | 5.5 | 7.5 | 11 | ||

| B | 40 | 107 | 46 | 2 | 1.3 | 2900 | 30 | 45 | 55 | |

| 20 | 26.5 | 42 | 2 | 0.5 | 1450 | 5.5 | 7.5 | 11 | ||

| C | 34 | 81 | 46 | 2 | 1.3 | 2900 | 22 | 30 | 45 | |

| 17.5 | 20 | 42 | 2 | 0.5 | 1450 | 4 | 5.5 | 7.5 | ||

| D | 29 | 61 | 46 | 2 | 1.3 | 2900 | 15 | 22 | 30 | |

| 15 | 15 | 42 | 2 | 0.5 | 1450 | 3 | 3 | 5.5 | ||

| TZE50-160 | A | 50 | 34 | 71 | 2 | 2.4 | 2900 | 11 | 15 | 15 |

| 25 | 8.4 | 69 | 1 | 0.8 | 1450 | 1.5 | 2.2 | 2.2 | ||

| B | 45 | 29 | 71 | 2 | 2.4 | 2900 | 7.5 | 11 | 15 | |

| 22.5 | 7 | 69 | 1 | 0.8 | 1450 | 1.5 | 1.5 | 2.2 | ||

| C | 38 | 22 | 71 | 2 | 2.4 | 2900 | 5.5 | 7.5 | 11 | |

| 19 | 5.5 | 69 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| D | 31 | 17 | 71 | 2 | 2.4 | 2900 | 3 | 4 | 5.5 | |

| 16.5 | 4 | 69 | 1 | 0.8 | 1450 | 1.1 | 1.1 | 1.1 | ||

| TZE50-200 | A | 62 | 52 | 68 | 2 | 2.6 | 2900 | 18.5 | 22 | 30 |

| 31 | 13 | 65.5 | 1 | 0.7 | 1450 | 3 | 3 | 4 | ||

| B | 56 | 46 | 68 | 2 | 2.6 | 2900 | 15 | 18.5 | 22 | |

| 28.5 | 11.5 | 65.5 | 1 | 0.7 | 1450 | 2.2 | 3 | 4 | ||

| C | 49 | 37 | 68 | 2 | 2.6 | 2900 | 11 | 15 | 18.5 | |

| 25 | 9 | 65.5 | 1 | 0.7 | 1450 | 1.5 | 2.2 | 3 | ||

| D | 43 | 28 | 68 | 2 | 2.6 | 2900 | 7.5 | 11 | 15 | |

| 22 | 7 | 65.5 | 1 | 0.7 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZE50-250 | A | 70 | 82 | 65 | 2 | 2.4 | 2900 | 30 | 37 | 55 |

| 35 | 20 | 62.5 | 2 | 0.7 | 1450 | 4 | 5.5 | 7.5 | ||

| B | 66 | 75 | 65 | 2 | 2.4 | 2900 | 30 | 37 | 45 | |

| 33 | 18.5 | 62.5 | 2 | 0.7 | 1450 | 4 | 5.5 | 7.5 | ||

| C | 60 | 60 | 65 | 2 | 2.4 | 2900 | 22 | 30 | 37 | |

| 30 | 15 | 62.5 | 2 | 0.7 | 1450 | 3 | 4 | 5.5 | ||

| D | 50 | 45 | 65 | 2 | 2.4 | 2900 | 15 | 18.5 | 22 | |

| 26 | 11 | 62.5 | 2 | 0.7 | 1450 | 2.2 | 3 | 3 | ||

| TZE50-315 | A | 87 | 115 | 56 | 3 | 2.1 | 2900 | 55 | 75 | 110 |

| 44 | 28 | 53 | 2 | 0.5 | 1450 | 11 | 11 | 15 | ||

| B | 80 | 100 | 56 | 3 | 2.1 | 2900 | 45 | 75 | 90 | |

| 40 | 24 | 53 | 2 | 0.5 | 1450 | 7.5 | 11 | 15 | ||

| C | 70 | 78 | 56 | 3 | 2.1 | 2900 | 30 | 45 | 55 | |

| 35 | 19 | 53 | 2 | 0.5 | 1450 | 5.5 | 7.5 | 11 | ||

| D | 57 | 57 | 56 | 3 | 2.1 | 2900 | 22 | 30 | 37 | |

| 30 | 14 | 53 | 2 | 0.5 | 1450 | 3 | 4 | 5.5 | ||

| TZE50-400 | A | 82 | 194 | 48 | 3 | 2 | 2900 | 110 | 160 | |

| 41 | 48 | 45 | 2 | 0.5 | 1450 | 15 | 22 | 30 | ||

| B | 78 | 175 | 48 | 3 | 2 | 2900 | 90 | 132 | 160 | |

| 39 | 43 | 45 | 2 | 0.5 | 1450 | 15 | 18.5 | 22 | ||

| C | 70 | 140 | 48 | 3 | 2 | 2900 | 75 | 90 | 132 | |

| 35 | 34 | 45 | 2 | 0.5 | 1450 | 11 | 15 | 18.5 | ||

| D | 60 | 102 | 48 | 3 | 2 | 2900 | 45 | 75 | 90 | |

| 30 | 25 | 45 | 2 | 0.5 | 1450 | 7.5 | 11 | 15 | ||

| TZE80-160 | A | 94 | 32 | 78 | 2 | 3 | 2900 | 15 | 18.5 | 30 |

| 47 | 8 | 76 | 2 | 0.8 | 1450 | 2.2 | 3 | 4 | ||

| B | 85 | 28 | 78 | 2 | 3 | 2900 | 11 | 15 | 18.5 | |

| 42 | 7 | 76 | 2 | 0.8 | 1450 | 2.2 | 2.2 | 3 | ||

| C | 76 | 23 | 78 | 2 | 3 | 2900 | 11 | 11 | 15 | |

| 38 | 5.5 | 76 | 2 | 0.8 | 1450 | 1.5 | 2.2 | 2.2 | ||

| D | 66 | 17 | 78 | 2 | 3 | 2900 | 5.5 | 7.5 | 11 | |

| 34 | 4 | 76 | 2 | 0.8 | 1450 | 1.1 | 1.1 | 1.5 | ||

| TZE80-200 | A | 103 | 54 | 76 | 1 | 3.2 | 2900 | 30 | 37 | |

| 51 | 13.5 | 74 | 4 | 0.8 | 1450 | 4 | 5.5 | 7.5 | ||

| B | 95 | 48 | 76 | 1 | 3.2 | 2900 | 22 | 30 | 37 | |

| 47 | 12 | 74 | 4 | 0.8 | 1450 | 3 | 4 | 5.5 | ||

| C | 84 | 38 | 76 | 1 | 3.2 | 2900 | 15 | 22 | 30 | |

| 41 | 9.5 | 74 | 4 | 0.8 | 1450 | 2.2 | 3 | 4 | ||

| D | 70 | 30 | 76 | 1 | 3.2 | 2900 | 11 | 15 | 22 | |

| 36 | 7.5 | 74 | 4 | 0.8 | 1450 | 1.5 | 2.2 | 3 | ||

| TZE80-250 | A | 127 | 82 | 74 | 2 | 3.5 | 2900 | 45 | 75 | 90 |

| 64 | 20 | 74 | 2 | 1.4 | 1450 | 7.5 | 11 | 15 | ||

| B | 120 | 76 | 74 | 2 | 3.5 | 2900 | 45 | 55 | 75 | |

| 60 | 19 | 74 | 2 | 1.4 | 1450 | 7.5 | 7.5 | 11 | ||

| C | 105 | 59 | 74 | 2 | 3.5 | 2900 | 30 | 45 | 55 | |

| 52 | 14.5 | 74 | 2 | 1.4 | 1450 | 4 | 5.5 | 7.5 | ||

| D | 87 | 45 | 74 | 2 | 3.5 | 2900 | 22 | 30 | 37 | |

| 46 | 11 | 74 | 2 | 1.4 | 1450 | 3 | 4 | 5.5 | ||

| TZE80-315 | A | 141 | 127 | 69 | 2 | 4 | 2900 | 90 | ||

| 70 | 33 | 69 | 2 | 1 | 1450 | 15 | 18.5 | 22 | ||

| B | 135 | 121 | 69 | 2 | 4 | 2900 | 75 | |||

| 66 | 30 | 69 | 2 | 1 | 1450 | 11 | 15 | 22 | ||

| C | 115 | 97 | 69 | 2 | 4 | 2900 | 55 | 75 | ||

| 56 | 24 | 69 | 2 | 1 | 1450 | 11 | 11 | 15 | ||

| D | 90 | 74 | 69 | 2 | 4 | 2900 | 37 | 45 | 75 | |

| 45 | 18 | 69 | 2 | 1 | 1450 | 5.5 | 7.5 | 11 | ||

| TZE80-400 | A | 171 | 187 | 61 | 3 | 3.5 | 2900 | 160 | ||

| 85 | 46 | 61 | 2 | 0.8 | 1450 | 22 | 30 | 45 | ||

| B | 159 | 170 | 61 | 3 | 3.5 | 2900 | 160 | |||

| 80 | 42 | 61 | 2 | 0.8 | 1450 | 18.5 | 30 | 37 | ||

| C | 135 | 130 | 61 | 3 | 3.5 | 2900 | 90 | 132 | ||

| 65 | 33 | 61 | 2 | 0.8 | 1450 | 15 | 18.5 | 30 | ||

| D | 116 | 95 | 61 | 3 | 3.5 | 2900 | 75 | 90 | 132 | |

| 53 | 25 | 61 | 2 | 0.8 | 1450 | 11 | 15 | 18.5 | ||

| TZE100-160 | A | 162 | 29 | 81 | 2 | 4.7 | 2900 | 22 | 30 | 37 |

| 81 | 7.2 | 81 | 2 | 1.4 | 1450 | 3 | 4 | 5.5 | ||

| B | 150 | 24 | 81 | 2 | 4.7 | 2900 | 15 | 22 | 30 | |

| 73 | 6 | 81 | 2 | 1.4 | 1450 | 2.2 | 3 | 4 | ||

| C | 130 | 17 | 81 | 2 | 4.7 | 2900 | 11 | 15 | 18.5 | |

| 63 | 4.3 | 81 | 2 | 1.4 | 1450 | 1.5 | 2.2 | 3 | ||

| D | 110 | 12 | 81 | 2 | 4.7 | 2900 | 7.5 | 11 | 15 | |

| 55 | 3 | 81 | 2 | 1.4 | 1450 | 1.1 | 1.5 | 2.2 | ||

| TZE100-200 | A | 193 | 50 | 81 | 2 | 3.7 | 2900 | 45 | 55 | 75 |

| 95 | 12.5 | 81 | 2 | 1 | 1450 | 5.5 | 7.5 | 11 | ||

| B | 180 | 44 | 81 | 2 | 3.7 | 2900 | 37 | 45 | 75 | |

| 90 | 10.5 | 81 | 2 | 1 | 1450 | 5.5 | 7.5 | 11 | ||

| C | 155 | 35 | 81 | 2 | 3.7 | 2900 | 30 | 37 | 45 | |

| 80 | 8.5 | 81 | 2 | 1 | 1450 | 4 | 5.5 | 7.5 | ||

| D | 135 | 26 | 81 | 2 | 3.7 | 2900 | 18.5 | 30 | 37 | |

| 70 | 6 | 81 | 2 | 1 | 1450 | 3 | 3 | 4 | ||

| TZE100-250 | A | 230 | 79 | 81 | 2 | 4 | 2900 | 75 | 90 | |

| 115 | 20 | 81 | 2 | 1 | 1450 | 11 | 15 | 18.5 | ||

| B | 218 | 73 | 81 | 2 | 4 | 2900 | 75 | 90 | ||

| 110 | 18 | 81 | 2 | 1 | 1450 | 11 | 11 | 15 | ||

| C | 190 | 58 | 81 | 2 | 4 | 2900 | 45 | 75 | 90 | |

| 100 | 14 | 81 | 2 | 1 | 1450 | 7.5 | 11 | 11 | ||

| D | 170 | 44 | 81 | 2 | 4 | 2900 | 37 | 45 | 75 | |

| 90 | 40 | 81 | 2 | 1 | 1450 | 5.5 | 7.5 | 7.5 | ||

| TZE100-315 | A | 250 | 126 | 78 | 2 | 5 | 2900 | 132 | ||

| 125 | 31 | 78 | 2 | 1.4 | 1450 | 18.5 | 30 | 37 | ||

| B | 240 | 120 | 78 | 2 | 5 | 2900 | 132 | 160 | ||

| 119 | 29 | 78 | 2 | 1.4 | 1450 | 18.5 | 22 | 30 | ||

| C | 203 | 97 | 78 | 2 | 5 | 2900 | 90 | 132 | 160 | |

| 104 | 24 | 78 | 2 | 1.4 | 1450 | 15 | 18.5 | 22 | ||

| D | 170 | 71 | 78 | 2 | 5 | 2900 | 75 | 75 | 110 | |

| 86 | 17.5 | 78 | 2 | 1.4 | 1450 | 11 | 11 | 15 | ||

| TZE100-400 | A | 300 | 194 | 74.5 | 3 | 6.4 | 2900 | |||

| 150 | 48 | 1.7 | 1450 | 37 | 45 | 75 | ||||

| B | 290 | 180 | 6.4 | 2900 | ||||||

| 145 | 44 | 1.7 | 1450 | 30 | 45 | 55 | ||||

| C | 260 | 145 | 6.4 | 2900 | ||||||

| 130 | 36 | 1.7 | 1450 | 22 | 30 | 45 | ||||

| D | 224 | 105 | 6.4 | 2900 | 110 | 160 | ||||

| 115 | 26 | 1.7 | 1450 | 15 | 22 | 30 | ||||

| TZE100-500 | A | 180 | 75 | 3 | 1.5 | 1450 | 75 | 90 | 110 | |

| B | 167 | 68 | 55 | 75 | 110 | |||||

| C | 142 | 53 | 37 | 55 | 75 | |||||

| D | 120 | 42 | 30 | 37 | 55 | |||||

| TZE150-200 | A | 320 | 44 | 83.5 | 2 | 6.4 | 2900 | 55 | 75 | |

| 160 | 11 | 83.5 | 2 | 1.7 | 1450 | 7.5 | 11 | 15 | ||

| B | 300 | 39 | 83.5 | 2 | 6.4 | 2900 | 45 | 75 | 90 | |

| 152 | 9.5 | 83.5 | 2 | 1.7 | 1450 | 7.5 | 11 | 15 | ||

| C | 265 | 30 | 83.5 | 2 | 6.4 | 2900 | 37 | 45 | 75 | |

| 140 | 7 | 83.5 | 2 | 1.7 | 1450 | 5.5 | 7.5 | 11 | ||

| D | 220 | 23 | 83.5 | 2 | 6.4 | 2900 | 22 | 30 | 45 | |

| 123 | 5 | 83.5 | 2 | 1.7 | 1450 | 3 | 4 | 5.5 | ||

| TZE150-250 | A | 390 | 74 | 82 | 3 | 6 | 2900 | 110 | 160 | |

| 195 | 18.5 | 82 | 2 | 1.4 | 1450 | 15 | 22 | 30 | ||

| B | 355 | 62 | 82 | 3 | 6 | 2900 | 90 | 110 | 160 | |

| 180 | 6 | 82 | 2 | 1.4 | 1450 | 15 | 18.5 | 22 | ||

| C | 325 | 46 | 82 | 3 | 6 | 2900 | 75 | 90 | 110 | |

| 160 | 11.5 | 82 | 2 | 1.4 | 1450 | 11 | 11 | 15 | ||

| TZE150-315 | A | 442 | 125 | 82.5 | 3 | 7 | 2900 | |||

| 220 | 32.5 | 81 | 3 | 1.7 | 1450 | 30 | 45 | 55 | ||

| B | 430 | 120 | 82.5 | 3 | 7 | 2900 | ||||

| 210 | 30 | 81 | 3 | 1.7 | 1450 | 30 | 37 | 55 | ||

| C | 372 | 94 | 82.5 | 3 | 7 | 2900 | 160 | |||

| 180 | 24 | 81 | 3 | 1.7 | 1450 | 22 | 30 | 37 | ||

| D | 310 | 68 | 82.5 | 3 | 7 | 2900 | 90 | 132 | 160 | |

| 150 | 17 | 81 | 3 | 1.7 | 1450 | 15 | 18.5 | 22 | ||

| TZE150-400 | A | 520 | 205 | 78.5 | 4 | 7 | 2900 | |||

| 260 | 51 | 77 | 3 | 1.8 | 1450 | 55 | 75 | 110 | ||

| B | 498 | 190 | 78.5 | 4 | 7 | 2900 | ||||

| 250 | 48 | 77 | 3 | 1.8 | 1450 | 55 | 75 | 90 | ||

| C | 453 | 151 | 78.5 | 4 | 7 | 2900 | ||||

| 225 | 38 | 77 | 3 | 1.8 | 1450 | 37 | 55 | 75 | ||

| D | 400 | 113 | 78.5 | 4 | 7 | 2900 | ||||

| 200 | 28 | 77 | 3 | 1.8 | 1450 | 30 | 37 | 55 | ||

| TZE150-500 | A | 300 | 77 | 74 | 3 | 2 | 1450 | 110 | 132 | |

| B | 283 | 72 | 74 | 3 | 2 | 1450 | 90 | 132 | 160 | |

| C | 233 | 59 | 74 | 3 | 2 | 1450 | 75 | 90 | 110 | |

| D | 208 | 45 | 74 | 3 | 2 | 1450 | 45 | 75 | 75 | |

| TZE150-560 | A | 335 | 104 | 74.5 | 4 | 2.4 | 1450 | 160 | ||

| B | 315 | 97 | 74.5 | 4 | 2.4 | 1450 | 132 | |||

| C | 260 | 80 | 74.5 | 4 | 2.4 | 1450 | 90 | 132 | 160 | |

| D | 216 | 60 | 74.5 | 4 | 2.4 | 1450 | 75 | 90 | 110 | |

| TZE150-630 | A | 360 | 115 | 63 | 4 | 2.4 | 1450 | |||

| B | 338 | 105.5 | ||||||||

| C | 274 | 82 | 132 | 160 | ||||||

| D | 220 | 60 | 75 | 110 | 160 | |||||

| TZE200-250 | A | 610 | 72 | 84.5 | 3 | 9 | 2900 | 160 | ||

| 305 | 17.5 | 83.5 | 3 | 2.4 | 1450 | 22 | 30 | 45 | ||

| B | 580 | 65 | 84.5 | 3 | 9 | 2900 | 160 | |||

| 290 | 16 | 83.5 | 3 | 2.4 | 1450 | 18.5 | 30 | 37 | ||

| C | 520 | 47 | 84.5 | 3 | 9 | 2900 | 110 | 132 | 160 | |

| 260 | 12 | 83.5 | 3 | 2.4 | 1450 | 15 | 18.5 | 30 | ||

| D | 470 | 32 | 84.5 | 3 | 9 | 2900 | 75 | 90 | 110 | |

| 240 | 8 | 83.5 | 3 | 2.4 | 1450 | 11 | 15 | 15 | ||

| TZE200-315 | A | 710 | 122 | 85.5 | 4 | 8.6 | 2900 | |||

| 350 | 30 | 84.5 | 3 | 2 | 1450 | 45 | 55 | 75 | ||

| B | 680 | 114 | 85.5 | 4 | 8.6 | 2900 | ||||

| 340 | 29 | 84.5 | 3 | 2 | 1450 | 37 | 55 | 75 | ||

| C | 600 | 87 | 85.5 | 4 | 8.6 | 2900 | ||||

| 300 | 22 | 84.5 | 3 | 2 | 1450 | 30 | 37 | 55 | ||

| D | 480 | 65 | 85.5 | 4 | 8.6 | 2900 | 132 | |||

| 250 | 15 | 84.5 | 3 | 2 | 1450 | 18.5 | 22 | 30 | ||

| TZE200-400 | A | 850 | 203 | 82 | 5 | 13 | 2900 | |||

| 426 | 50 | 81 | 3 | 3.5 | 1450 | 90 | 110 | 160 | ||

| B | 830 | 150 | 82 | 5 | 13 | 2900 | ||||

| 410 | 47 | 81 | 3 | 3.5 | 1450 | 75 | 110 | 132 | ||

| C | 750 | 145 | 82 | 5 | 13 | 2900 | ||||

| 370 | 36.5 | 81 | 3 | 3.5 | 1450 | 55 | 75 | 110 | ||

| D | 670 | 106 | 82 | 5 | 13 | 2900 | ||||

| 332 | 27 | 81 | 3 | 3.5 | 1450 | 45 | 55 | 75 | ||

| TZE200-500 | A | 495 | 84 | 81 | 4 | 2.9 | 1450 | |||

| B | 470 | 79 | 160 | |||||||

| C | 400 | 63 | 110 | 160 | ||||||

| D | 330 | 48 | 75 | 90 | 132 | |||||

| TZE200-560 | A | 540 | 105 | 79.5 | 5 | 3 | 1450 | |||

| B | 510 | 98 | ||||||||

| C | 460 | 81 | 160 | |||||||

| D | 350 | 62 | 110 | 132 | ||||||

| TZE200-630 | A | 580 | 132 | 77.5 | 5 | 3.5 | 1450 | |||

| B | 550 | 125 | ||||||||

| C | 468 | 100 | ||||||||

| D | 372 | 75 | 132 | |||||||

| TZE250-315 | A | 545 | 27 | 86.5 | 3 | 2.9 | 1450 | 55 | 75 | 110 |

| B | 528 | 25 | 55 | 75 | 90 | |||||

| C | 480 | 19 | 37 | 55 | 75 | |||||

| D | 434 | 13 | 30 | 37 | 45 | |||||

| TZE250-400 | A | 660 | 49 | 87.5 | 5 | 3.2 | 1450 | 132 | 160 | |

| B | 630 | 46 | 110 | 160 | ||||||

| C | 565 | 36 | 75 | 110 | 160 | |||||

| D | 500 | 24 | 55 | 75 | 90 | |||||

| TZE250-500 | A | 800 | 82 | 83 | 5 | 5 | 1450 | |||

| B | 770 | 76 | ||||||||

| C | 700 | 58 | 160 | |||||||

| D | 630 | 42 | 110 | 160 | ||||||

| TZE250-560 | A | 860 | 106 | 82 | 5 | 4.2 | 1450 | |||

| B | 830 | 98 | ||||||||

| C | 760 | 78 | ||||||||

| D | 665 | 57 | 160 | |||||||

| TZE250-630 | A | 855 | 128 | 80.5 | 6 | 4.2 | 1450 | |||

| B | 816 | 119 | ||||||||

| C | 720 | 96 | ||||||||

| D | 625 | 71 | ||||||||

| TZE300-400 | A | 1050 | 48 | 87 | 4 | 5.8 | 1450 | |||

| B | 1010 | 45 | 160 | |||||||

| C | 900 | 34 | 132 | 160 | 160 | |||||

| D | 780 | 26 | 90 | 132 | ||||||

| TZE300-500 | A | 1240 | 78 | 88 | 5 | 5.8 | 1450 | |||

| B | 1170 | 75 | ||||||||

| C | 1015 | 57 | ||||||||

| D | 870 | 42 | 160 | |||||||

| TZE300-560 | A | 1340 | 104 | 87 | 6 | 5.2 | 1450 | |||

| B | 1280 | 9 | ||||||||

| C | 1140 | 77 | ||||||||

| D | 950 | 56 | ||||||||

| TZE300-630 | A | 1450 | 132 | 85 | 6 | 5.5 | 1450 | |||

| B | 1375 | 125 | ||||||||

| C | 1170 | 100 | ||||||||

| D | 950 | 75 | ||||||||

| TZE400-500 | A | 1870 | 74 | 88 | 6 | 6.3 | 1450 | |||

| B | 1800 | 70 | ||||||||

| C | 1520 | 52 | ||||||||

| D | 1300 | 38 | ||||||||

| TZE400-560 | A | 2040 | 98 | 88 | 6 | 7.5 | 1450 | |||

| B | 1950 | 91 | ||||||||

| C | 1760 | 74 | ||||||||

| D | 1500 | 54 | ||||||||

| TZE400-630 | A | 2390 | 125 | 88 | 7 | 8.3 | 1450 | |||

| B | 2280 | 117 | ||||||||

| C | 1960 | 95 | ||||||||

| D | 1610 | 70 | ||||||||

二、实物图: