| Meaning | TCZ80-65-160 |

| T | Code of enterprise |

| C | Magnetic drive |

| Z | Self-priming |

| 80 | The inlet dia i 80mm |

| 65 | The out let dia is 65mm |

| 160 | Nominal dia of impeller is 160mm |

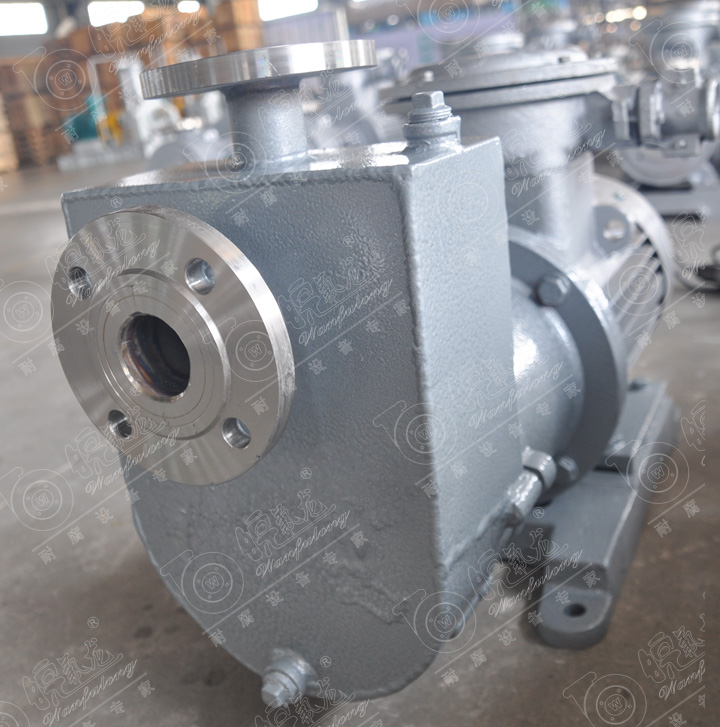

一、Product Introduction:

Product overview:

Non-leakage magnetic self-priming pump (shorter form: magnetic self-priming pump) is application of modern magnetic principles, which is a new type pump using the magnetic transmission of permanent magnet to implement torque’s contactless transmission, adopting design and structure of external mixing type axial backwater, thereof, when electric motor drives outer rotor(i.e. outer magnetic steel) assembly rotating , under magnetic field, magnetic line of force pass through distance sleeve drive inner rotor(i.e. inner magnetic steel) assembly rotating synchronously with impeller. The purpose of pumping media without leaking is due to the media closed in still distance sleeve. The pump body is composed by suction chamber, liquid storage chamber, volute casing, reflowing valve, air-liquid-isolating chamber, etc. Under centrifugal force after start-up, the rest liquid in suction chamber and the air in inlet pipeline would be stirred into air-liquid mixture, the mixture would be to air-liquid-isolating chamber through volute casing, within flow velocity slowing down, the air and liquid be separated, liquid outlet discharges the air, liquid returns to pump inside through reflowing valve. Through many circulations, air in liquid inlet be totally discharged, which makes pump inside being vacuum degree to get purpose of self-priming. This new design industrial pump, with many characteristics of full sealing, No leakage, No pollution and energy-efficient, completely solve the problem of shaft seal leakage of mechanical pump. Its performance already reaches international standard, thus can replace the expensive imported chemical pump.

Design features:

1. TCZ non-leakage magnetic self priming pump is the combination of Non-leakage magnetic driven pump and self-priming centrifugal pump. It is a new type magnetic driven pump with characteristics of full sealing, no leakage, no pollution and strong self-priming, which is designed voluntarily by us.

2. The flowing-passed components like pump body, inner rotor, pump cover, impeller, distance sleeve, etc, are all made of superior stainless steel or special materials.

3. New type permanent magnet with good magnetism, high temperature resistant and No demagnetization is selected.

4. Shaft sleeve, sleeve bearings be made of graphite and PTFE material with good characteristic of superior wear resistance and high temperature resistance, lubrication groove setting, which guarantee the pump’s working life.

5. The design of self-priming and gas-liquid mixture has strong function of self-priming, the height can reach 4 meters.

6. Enclosed static seal completely solves the problem of dielectric leakage.

7. No need of independent lubrication and cooling water, reducing energy consumption.

8. Direct coupling pull back design, No need to dismount pipe, easier maintenance.

9. Horizontal mount, compact structure, low voice, small vibration, small occupation and stable operation.

10. No contact and no friction, change coupling transmission to synchronic pulling. Power consumption of small, high efficiency, and has a damping effect, reducing vibration on the pump motor and pump in the effects of cavitations vibration when the impact of the motor.

Application:

Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery media of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range:

Design pressure: 1.6Mpa

Flow: 2-200m3/h

Head: 12-125m

Power: 1.1-55kw

Applicable temperature: -30~120℃, can be up to 350℃ if using new material.

The optional accessories: preventive idling running device, monitoring of leakage device, monitoring of temperature device

Notes: Pls indicate during ordering if the proportion of delivering media is larger than 1.3mg/cm3. No idle running. No delivering media with particle or crystalline.

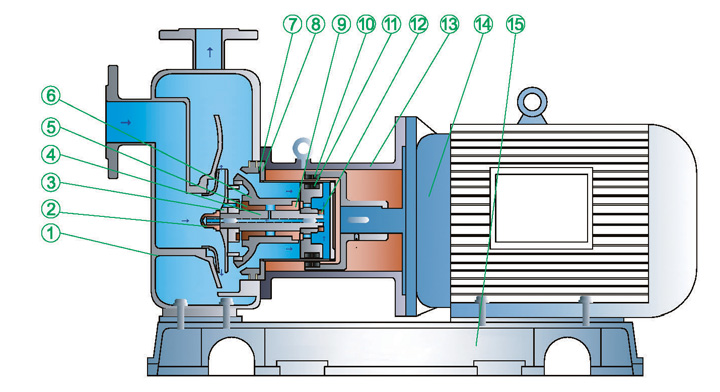

二、Structure drawing:

| Part | Material | Part | Material | Part | Material |

| 1.pump body | 304/316/316L | 6.pump cover | 304/316/316L | 11.inner magnet | magnet/304/316/316L |

| 2.impeller nut | 304/316/316L | 7.gasket | PTFE | 12.back nut | 304/316/316L |

| 3.impeller | 304/316/316L | 8.distance sleeve | 304/316/316L | 13.connecting | HT200 |

| 4.pump shaft | 304/316/316L | 9.back bearing sleeve | Graphite/SIC | 14.motor | per client requested |

| 5.front bearing sleeve | GRAPHITE/SIC | 10.outer magnet | permenant magnet/HT200 | 15.base plate | HT200 |

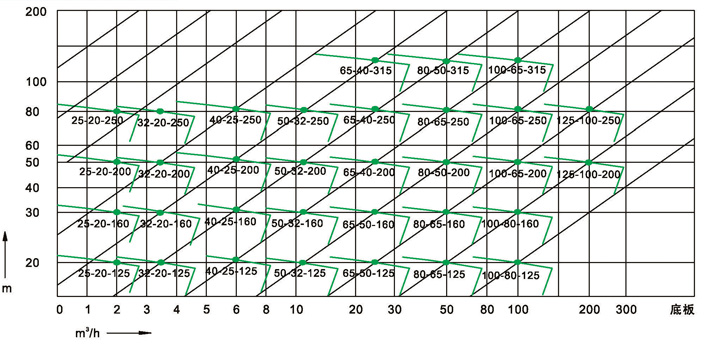

三、Performance Curve:

四、Performance data sheet:

| Type |

Rotating speed |

Flow m3/h |

Head m |

Efficiency % |

NPSH m |

Inlet X Outlet mm |

Power kw |

Weight kg |

| TCZ25-20-125 | 2900 | 1.5 | 22 | 18 | 2.5 | 25×20 | 1.1 | 80 |

| 2 | 20 | 20 | 2.5 | |||||

| 3.2 | 18.5 | 24 | 3 | |||||

| TCZ25-20-160 | 2900 | 1.5 | 34.3 | 19 | 2.5 | 25×20 | 1.5 | 85 |

| 2 | 32 | 22 | 2.5 | |||||

| 3.2 | 29.6 | 25 | 3 | |||||

| TCZ25-20-200A | 2900 | 1.5 | 42 | 28 | 2.5 | 25×20 | 3 | 155 |

| 2 | 40 | 32 | 2.5 | |||||

| 3.2 | 38 | 30 | 3 | |||||

| TCZ25-20-200 | 2900 | 1.5 | 52.5 | 18 | 2.5 | 25×20 | 3 | 160 |

| 2 | 50 | 20 | 2.5 | |||||

| 3.2 | 48 | 22 | 3 | |||||

| TCZ25-20-250A | 2900 | 1.5 | 62 | 26 | 2.5 | 25×20 | 5.5 | 210 |

| 2 | 60 | 30 | 2.5 | |||||

| 3.2 | 58 | 28 | 3 | |||||

| TCZ25-20-250B | 2900 | 1.5 | 72 | 26 | 2.5 | 25×20 | 7.5 | 230 |

| 2 | 70 | 30 | 2.5 | |||||

| 3.2 | 68 | 28 | 3 | |||||

| TCZ25-20-250 | 2900 | 1.5 | 82 | 12 | 2.5 | 25×20 | 7.5 | 240 |

| 2 | 80 | 18 | 2.5 | |||||

| 3.2 | 78.5 | 26 | 3 | |||||

| TCZ32-20-125 | 2900 | 2 | 22 | 20.5 | 2.5 | 32×20 | 1.5 | 83 |

| 3.2 | 20 | 20 | 2.5 | |||||

| 5.5 | 18.5 | 18 | 3 | |||||

| TCZ32-20-160 | 2900 | 2 | 34.3 | 20.5 | 2.5 | 32×20 | 2.2 | 90 |

| 3.2 | 32 | 20 | 2.5 | |||||

| 5.5 | 29.6 | 18 | 3 | |||||

| TCZ32-20-200A | 2900 | 2 | 42 | 25 | 2.5 | 32×20 | 4 | 180 |

| 3.2 | 40 | 24 | 2.5 | |||||

| 5.5 | 38 | 21.5 | 3 | |||||

| TCZ32-20-200 | 2900 | 2 | 52.5 | 32 | 2.5 | 32×20 | 4 | 180 |

| 3.2 | 50 | 36 | 2.5 | |||||

| 5.5 | 48 | 34 | 3 | |||||

| TCZ32-20-250A | 2900 | 2 | 62 | 22 | 2.5 | 32×20 | 7.5 | 250 |

| 3.2 | 60 | 26 | 2.5 | |||||

| 5.5 | 58 | 28.5 | 3 | |||||

| TCZ32-20-250B | 2900 | 2 | 72 | 26 | 2.5 | 32×20 | 7.5 | 250 |

| 3.2 | 70 | 30 | 2.5 | |||||

| 5.5 | 68 | 28 | 3 | |||||

| TCZ32-20-250 | 2900 | 2 | 82 | 26 | 2.5 | 32×20 | 7.5 | 310 |

| 3.2 | 80 | 30 | 2.5 | |||||

| 5.5 | 78.5 | 28 | 3 | |||||

| TCZ40-25-125 | 2900 | 4.4 | 22 | 16 | 2.5 | 40×25 | 1.5 | 140 |

| 6.3 | 20 | 20 | 2.5 | |||||

| 8.3 | 18.5 | 23 | 3 | |||||

| TCZ40-25-160 | 2900 | 4.4 | 34.3 | 30 | 2.5 | 40×25 | 3 | 160 |

| 6.3 | 32 | 31 | 2.5 | |||||

| 8.3 | 29.6 | 32 | 3 | |||||

| TCZ40-25-200A | 2900 | 4.4 | 42 | 30 | 2.5 | 40×25 | 4 | 200 |

| 6.3 | 40 | 31 | 2.5 | |||||

| 8.3 | 38 | 32 | 3 | |||||

| TCZ40-25-200 | 2900 | 4.4 | 52.5 | 26 | 2.5 | 40×25 | 5.5 | 210 |

| 6.3 | 50 | 33 | 2.5 | |||||

| 8.3 | 48 | 32 | 3 | |||||

| TCZ40-25-250A | 2900 | 4.4 | 62 | 20 | 2.5 | 40×25 | 11 | 254 |

| 6.3 | 60 | 23 | 2.5 | |||||

| 8.3 | 58 | 30 | 3 | |||||

| TCZ40-25-250B | 2900 | 4.4 | 72 | 24 | 2.5 | 40×25 | 11 | 240 |

| 6.3 | 70 | 28 | 2.5 | |||||

| 8.3 | 68 | 28 | 3 | |||||

| TCZ40-25-250 | 2900 | 4.4 | 82 | 24 | 2.5 | 40×25 | 11 | 280 |

| 6.3 | 80 | 28 | 2.5 | |||||

| 8.3 | 78.5 | 28 | 3 | |||||

| TCZ50-32-125 | 2900 | 7.5 | 22 | 43 | 2 | 50×32 | 2.2 | 167 |

| 12.5 | 20 | 51 | 2 | |||||

| 15 | 18.5 | 49 | 2.5 | |||||

| TCZ50-32-160 | 2900 | 7.5 | 34.3 | 35 | 2 | 50×32 | 3 | 192 |

| 12.5 | 32 | 47 | 2 | |||||

| 15 | 29.6 | 47 | 2.5 | |||||

| TCZ50-32-200A | 2900 | 7.5 | 42 | 28 | 2 | 50×32 | 7.5 | 238 |

| 12.5 | 40 | 39 | 2 | |||||

| 15 | 38 | 43 | 2.5 | |||||

| TCZ50-32-200 | 2900 | 7.5 | 52.5 | 28 | 2 | 50×32 | 7.5 | 285 |

| 12.5 | 50 | 40 | 2 | |||||

| 15 | 48 | 48 | 2.5 | |||||

| TCZ50-32-250A | 2900 | 7.5 | 62 | 23 | 2 | 50×32 | 7.5 | 300 |

| 12.5 | 60 | 33 | 2 | |||||

| 15 | 58 | 36.5 | 2.5 | |||||

| TCZ50-32-250B | 2900 | 7.5 | 72 | 23 | 2 | 50×32 | 11 | 324 |

| 12.5 | 70 | 33 | 2 | |||||

| 15 | 68 | 36.5 | 2.5 | |||||

| TCZ50-32-250 | 2900 | 7.5 | 82 | 23 | 2 | 50×32 | 11 | 344 |

| 12.5 | 80 | 33 | 2 | |||||

| 15 | 78.5 | 36.5 | 2.5 | |||||

| TCZ65-50-125 | 2900 | 15 | 21.8 | 46 | 2 | 65×50 | 3 | 200 |

| 25 | 20 | 56 | 2 | |||||

| 30 | 18.5 | 65 | 2.5 | |||||

| TCZ65-50-160 | 2900 | 15 | 35 | 46 | 2 | 65×50 | 5.5 | 225 |

| 25 | 32 | 56 | 2 | |||||

| 30 | 30 | 65 | 2.5 | |||||

| TCZ65-40-200A | 2900 | 15 | 42 | 41 | 2 | 65×40 | 11 | 290 |

| 25 | 40 | 52 | 2 | |||||

| 30 | 38 | 53.5 | 2.5 | |||||

| TCZ65-40-200 | 2900 | 15 | 53 | 34 | 2 | 65×40 | 11 | 310 |

| 25 | 50 | 46 | 2 | |||||

| 30 | 47 | 50 | 2.5 | |||||

| TCZ65-40-250A | 2900 | 15 | 62 | 28 | 2 | 65×40 | 15 | 180 |

| 25 | 60 | 39 | 2 | |||||

| 30 | 58 | 42.5 | 2.5 | |||||

| TCZ65-40-250B | 2900 | 15 | 72 | 28 | 2 | 65×40 | 18.5 | 300 |

| 25 | 70 | 39 | 2 | |||||

| 30 | 68 | 42.5 | 2.5 | |||||

| TCZ65-40-250 | 2900 | 15 | 82 | 33 | 2 | 65×40 | 18.5 | 340 |

| 25 | 80 | 48 | 2 | |||||

| 30 | 78 | 50 | 2.5 | |||||

| TCZ65-40-315A | 2900 | 15 | 105 | 28 | 2.5 | 65×40 | 30 | 521 |

| 25 | 100 | 39 | 2.5 | |||||

| 30 | 98 | 42.5 | 3 | |||||

| TCZ65-40-315 | 2900 | 15 | 127 | 28 | 2.5 | 65×40 | 30 | 611 |

| 25 | 125 | 39 | 2.5 | |||||

| 30 | 123 | 42.5 | 3 | |||||

| TCZ80-65-125 | 2900 | 30 | 22.5 | 52 | 3 | 80×65 | 5.5 | 280 |

| 50 | 20 | 65 | 3 | |||||

| 60 | 18 | 70 | 3.5 | |||||

| TCZ80-65-160 | 2900 | 30 | 36 | 60 | 2.5 | 80×65 | 11 | 343 |

| 50 | 32 | 64 | 2.5 | |||||

| 60 | 29 | 53 | 3 | |||||

| TCZ80-50-200A | 2900 | 30 | 42 | 53 | 2.5 | 80×50 | 15 | 431 |

| 50 | 40 | 63 | 2.5 | |||||

| 60 | 38 | 62 | 3 | |||||

| TCZ80-50-200 | 2900 | 30 | 53 | 53 | 2.5 | 80×50 | 15 | 454 |

| 50 | 50 | 63 | 2.5 | |||||

| 60 | 47 | 55 | 3 | |||||

| TCZ80-50-250A | 2900 | 30 | 62 | 44 | 2.5 | 80×50 | 22 | 410 |

| 50 | 60 | 57 | 2.5 | |||||

| 60 | 58 | 59 | 3 | |||||

| TCZ80-50-250B | 2900 | 30 | 72 | 44 | 2.5 | 80×50 | 30 | 490 |

| 50 | 70 | 57 | 2.5 | |||||

| 60 | 68 | 59 | 3 | |||||

| TCZ80-50-250 | 2900 | 30 | 84 | 48 | 2.5 | 80×50 | 30 | 504 |

| 50 | 80 | 56 | 2.5 | |||||

| 60 | 75 | 50 | 3 | |||||

| TCZ80-50-315A | 2900 | 30 | 105 | 39 | 2.5 | 80×50 | 37 | 1056 |

| 50 | 100 | 51 | 2.5 | |||||

| 60 | 98 | 52.5 | 3 | |||||

| TCZ80-50-315 | 2900 | 30 | 128 | 39 | 2.5 | 80×50 | 37 | 1247 |

| 50 | 125 | 51 | 2.5 | |||||

| 60 | 123 | 52.5 | 3 | |||||

| TCZ100-80-125 | 2900 | 60 | 24 | 64 | 4 | 100×80 | 11 | 300 |

| 100 | 20 | 65 | 4.5 | |||||

| 120 | 16.5 | 63 | 5 | |||||

| TCZ100-80-160 | 2900 | 60 | 36 | 60 | 3.5 | 100×80 | 15 | 408 |

| 100 | 32 | 70 | 4 | |||||

| 120 | 28 | 65 | 5 | |||||

| TCZ100-65-200A | 2900 | 60 | 42 | 63 | 3 | 100×65 | 18.5 | 488 |

| 100 | 40 | 72 | 3.6 | |||||

| 120 | 38 | 71 | 4.8 | |||||

| TCZ100-65-200 | 2900 | 60 | 54 | 63 | 3 | 100×65 | 22 | 550 |

| 100 | 50 | 68 | 3.6 | |||||

| 120 | 47 | 56 | 4.8 | |||||

| TCZ100-65-250A | 2900 | 60 | 62 | 57 | 3.5 | 100×65 | 30 | 566 |

| 100 | 60 | 68 | 3.8 | |||||

| 120 | 58 | 67 | 4.8 | |||||

| TCZ100-65-250B | 2900 | 60 | 72 | 57 | 3.5 | 100×65 | 37 | 642 |

| 100 | 70 | 68 | 3.8 | |||||

| 120 | 68 | 67 | 4.8 | |||||

| TCZ100-65-250 | 2900 | 60 | 87 | 60 | 3.5 | 100×65 | 37 | 711 |

| 100 | 80 | 68 | 3.8 | |||||

| 120 | 74.5 | 67 | 4.8 | |||||

| TCZ100-65-315A | 2900 | 60 | 105 | 48 | 3 | 100×65 | 75 | 948 |

| 100 | 100 | 62 | 3.6 | |||||

| 120 | 98 | 64 | 4.2 | |||||

| TCZ100-65-315 | 2900 | 60 | 133 | 63 | 3 | 100×65 | 75 | 1278 |

| 100 | 125 | 65 | 3.6 | |||||

| 120 | 118 | 62 | 4.2 | |||||

| TCZ125-100-200 | 2900 | 120 | 57.5 | 63 | 4.5 | 125×100 | 45 | 887 |

| 200 | 50 | 75 | 4.5 | |||||

| 240 | 44.5 | 74 | 5 | |||||

| TCZ125-100-250A | 2900 | 120 | 62 | 63 | 3.8 | 125×100 | 55 | 855 |

| 200 | 60 | 75 | 4.2 | |||||

| 240 | 58 | 74 | 5 | |||||

| TCZ125-100-250B | 2900 | 120 | 72 | 57 | 3.8 | 125×100 | 75 | 1215 |

| 200 | 70 | 68 | 4.2 | |||||

| 240 | 68 | 67 | 5 | |||||

| TCZ125-100-250 | 2900 | 120 | 87 | 57 | 3.8 | 125×100 | 75 | 1219 |

| 200 | 80 | 68 | 4.2 | |||||

| 240 | 72 | 67 | 5 |